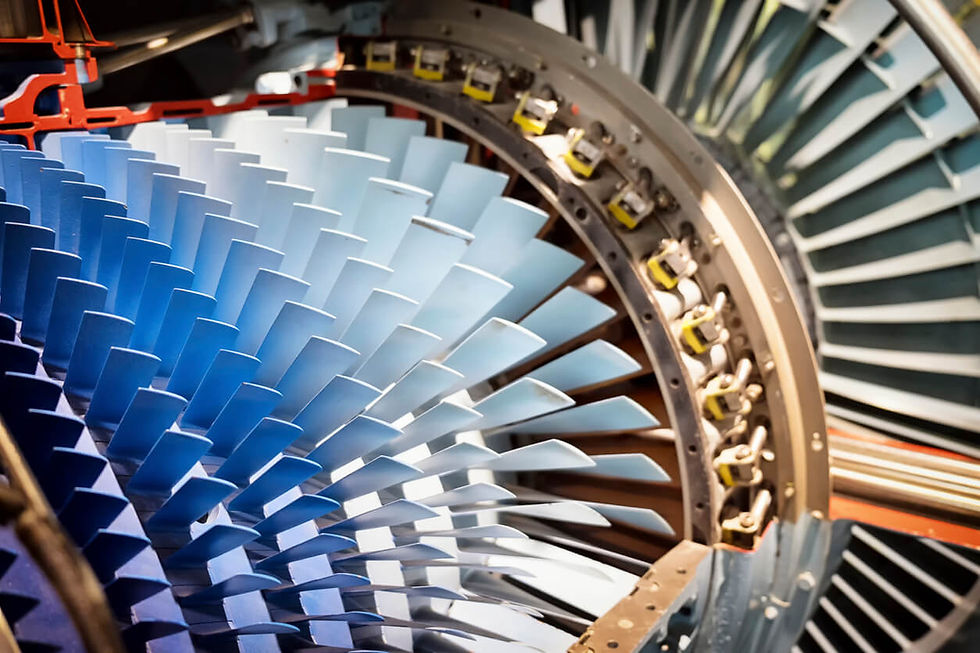

Tigress.ai is currently capable of monitoring the health of a gas turbine from existing data which is monitored and analysed thousands of times a minute to locate anomalies within and outside of the turbine. So vibration levels of bearings, blading and combustion systems will tell the owner of the turbine what issues are coming their way from the standard data used to keep the turbine in order.

Tigress.ai is now looking at systems and sensors which offer the ability to monitor measurements from the actual power turbine blades whilst they are operating at full speed, temperature and load. These sensors can remain in operation for 40,000 hours keeping a firm eye on the turbine’s behaviour for all that time and avoiding maintenance and potential failure issues

These sensors must be attached to the high temperature blading during the standard overhaul process and then you are in business. They have been proven reliable, safe and accurate by leading OEM’s and will happily replace the need to take out expensive long term maintenance contracts.

A continuous Temperature Measurement System, TurboTrack is designed for the long haul.

The sensors or real time blade tip health system will:

Extend the running time between maintenance outages

Predict machine need for maintenance

Help increase energy production

Extend the life of gas turbines

Reduce the risk of failure

If you would like to see how Tigress.ai can extend the life of your turbine, please book in for a demonstration